Centrifugal Separation: thebest approach to cleaning fluids

On-site cleaning of industrial fluids – oils, coolants and wash liquids – is a must in most modern manufacturing operations. Efficient cleaning prolongs the lifetime of fluids, thus lowering production costs and reducing environmental impact. Furthermore, clean fluids are crucial for maintaining a consistent quality in the manufacturing process and minimising downtime for maintenance and service.

This booklet explains the working principle of centrifugal separation – the most robust and efficient cleaning method for industrial fluids in the world today.

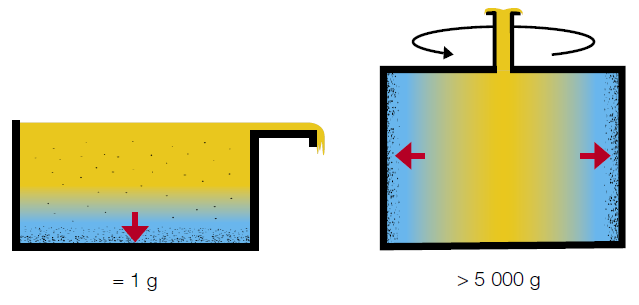

Based on nature’s own force – but 5 000 times stronger

In a tank, thanks to the force of gravity, the light and the heavy phase of a polluted fluid are gradually separated, and the heavy particles sink to the bottom. As a separation method, this performs poorly, because it is slow and there is usually a large mixing phase left unseparated.

In a centrifugal separator, the force of gravity is replaced with a centrifugal force that can be more than 5000 times stronger than the force of gravity. The separation will naturally be significantly faster.

Well-known principles made more effective

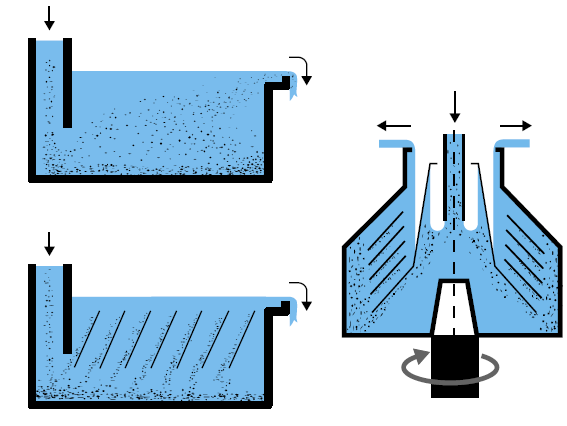

If you supplement the separation tank with buffer plates, the sinking particles are stopped earlier and have a larger surface area to fasten to. The separation goes faster.

In the the centrifugal separator, the effectiveness is increased by a disk stack. The principle is still the same as in the tank. Heavy particles are drawn to the separator´s walls by centrifugal force. Lighter particles, which tend to follow the fluid towards the separator’s centre, are hindered by the disk stack, change direction and end up with the heavy particles by the wall. The centrifugal separator can be used both to remove particles and to easily separate different fluids from one another.

Robust design requires minimal maintenance

A centrifugal separator has few moving parts and requires very little maintenance. It is supremely easy to use and operates independently without special monitoring. In most cases, the separator is installed in a bypass system and operates continuously. This means that cleaning can be carried out around the clock, even if the system to be cleaned is not operating. There are also separators that can easily be moved between different machines.

Depending on the content of sludge and particles, a separator with either automatic or manual emptying function can be chosen.

009821-88934322

009821-88934322