Non-genuine gaskets in Iran Market

To achieve the best sealing performance, gasket design and material properties must match the intended application.

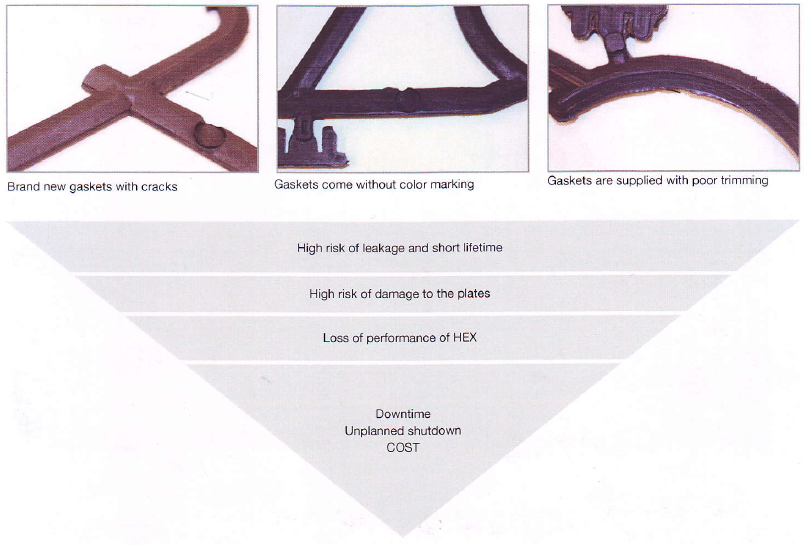

Although a gasket may look the original, it may not perform like an Alfa Laval gasket. The manufacturing process – as well as the composition of the gasket’s rubber components – are different.

Genuine rubber gaskets ensure tighter seals, longer lifetime and more uptime for gasketed plate heat exchangers.

Using genuine plates safeguards the structural integrity of heat exchangers as well as the media passing through the units.

Genuine Alfa Laval gaskets are carefully manufactured with emphasis on:

- Type and quality of rubber

- Profile

- Thickness

- Width

Background

What happens if you replace Alfa Laval gaskets on an Alfa Laval plate heat exchanger with similar gasket from another parts supplier?

Designing a gasket for a particular heat exchanger type requires detailed analysis of both the plate and the gasket. Alfa Laval and selected expert suppliers developed new or improved rubber compounds for Alfa Laval plate heat exchangers by determining the exact proportions of the different ingredients in the rubber formulation.

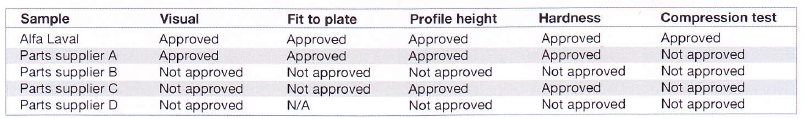

To discover whether gaskets from different parts suppliers stand up to the task, Alfa Laval conducted thorough investigations to evaluate the quality of non-original gaskets intended as replacement parts for Alfa Laval plate heat exchangers.

The surface of the gasket can be analyzed by sight, but it is impossible to judge the material properties without testing.

Test results from Alfa Laval laboratory in Sweden

The general conclusion is that the gaskets from other parts suppliers are manufactured with less precision and lower quality than Alfa Laval gaskets. The gaskets generally fail standard Alfa Laval requirements in several areas.

Conclusion

Manufactured to precisely the correct tolerance and material specifications. Alfa Laval gaskets are subject to stringent quality control producers. It has been proven that it pays to invest in Alfa Laval gaskets. Using non-Alfa Laval spare parts that do not match the original specifications can contributes to less reliable PHE performance and put worker safety as well as the safety of your plant and environment at risk.

In addition, the cost of using non-Alfa Laval spare parts can have a significant – and unexpected – impact on your operating and maintenance budget.

009821-88934322

009821-88934322